Thermoforming & vacuum forming

Thermoforming heats a plastic sheet, allowing it to bend into a mold, creating a detailed, stress-free part. This process offers flexibility in adjusting wall thickness and material properties without costly tooling changes.

A selection of thermoplastic materials can be used in these processes, including the following:

- Acrylic (PMMA)

- Polystyrene (PS)

- Polyvinyl chloride (PVC)

- High-density polyethylene (HDPE)

- Polypropylene (PP)

- Acrylonitrile butadiene styrene (ABS)

Vacuum forming is a simplified version of thermoforming:

In this process, a plastic sheet is heated, stretched over a mold, and shaped by a vacuum, creating permanent objects like signs and protective covers. The vacuum tightens the malleable plastic over the mold, producing a highly detailed end product.

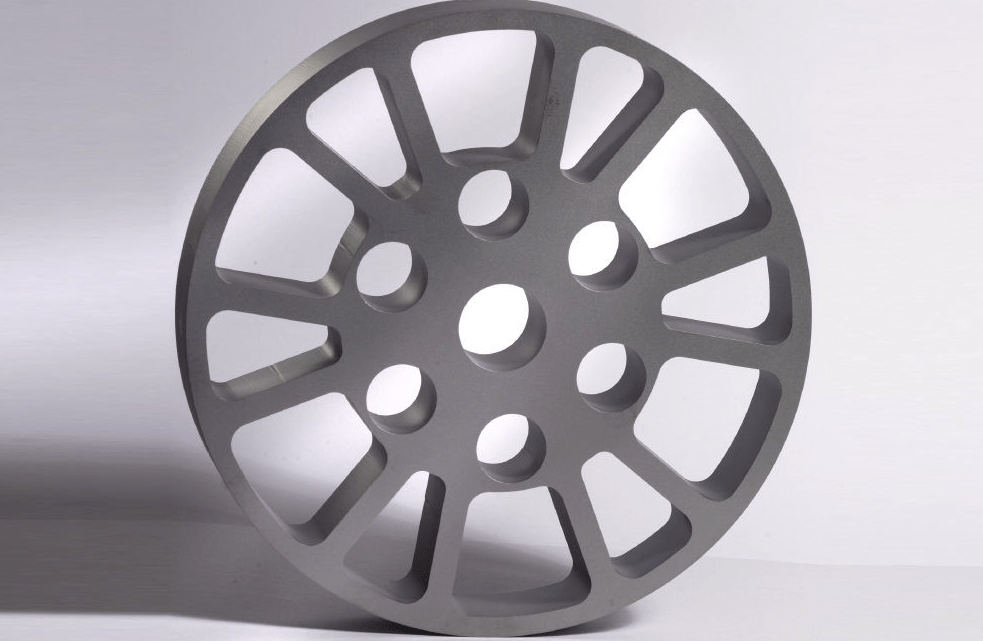

Our precise cutting service allows you to pay only for what you need

Use the service for acrylic (PMMA) as an excellent alternative to glass, or choose polycarbonate for shatterproof glass and greenhouses. We can cut all types of plastic that we have in stock, such as PET, PET-G, Nylon (Polyamide), PVC foam sheets, polypropylene, extruded acetal (POM). We typically cut with an accuracy of +/- 1 mm, which suits the majority of our customers and helps us deliver a quality service.

The maximum dimension is 2150 x 7000 mm.

If you require higher accuracy, you can contact us, and we can use our CNC routers to meet your needs. If you have any special requirements like drilled holes, rounded corners, cutouts, or polishing, we can also assist you.

Services

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.