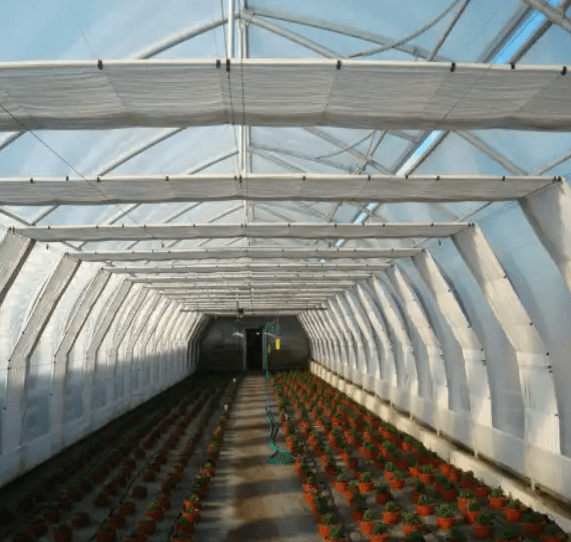

Greenhouse Agro Tunnel

Discover the advantages of the Agro Tunnel Greenhouse. This high-tech professional greenhouse is suitable for all weather conditions. We offer the Agro Tunnel Greenhouse in 8m or 7m width.

The Foundation of greenhouse Agro Tunnel

Constructed as a foundational point under each support. Embedment supports in the holes with a diameter of Ø 400 mm and 900 mm deep, filled with C16/20 concrete on ballast and sand.

Ventilation: roof ventilation on one side. Doors: 1 piece, 2.45 m x 2.50 m, two-part sliding doors. Covering: the roof, sides and gables with double. Inflated plastic film – the film at the bottom is secured with steel and PVC clips. Alternatively, 10mm or 16mm thick polycarbonate channel can be used. Galvanized screws will be used to connect the structure.

Please note that technical terms and measurements may vary in different construction contexts. It’s always a good idea to consult with professionals or experts in the field for precise specifications

Description of the Construction of the Tunnel:

Structural Elements: Supporting structure of galvanized steel pipes Ø 60.3 mm. Assembly of galvanized steel pipes with Ø35 x 1.5 mm connecting arches and props. Props made of Ø60.3 mm pipes with a length of 2.50 m. Film will be used to attach the steel strip (along with plastic), and as an additional feature, the concentration of the longitudinal arches at their ends. Concentration of the cross at the intersection of the columns. All structural elements are connected with screws and clamps.

SYSTEM OF SUNSHADE CURTAINS – THERMAL INSULATION AND LABELING

Materials, Lines, Drawstrings, Plastic Parts, Tight Aprons Shade Material BONAR PH 55 Light Transmission 45% Energy Efficiency 58% Fabric guidance with a galvanized pipe Rope drive at the top implemented with RIDDER RW gear motor – 1 piece per tunnel Control Section

Materials: Curtains are produced with automatic devices for shading, thermal insulation, and blackout curtains for all types of greenhouses and foil tunnels using materials from the German company Novavert, the Swedish company Ludwig Svensson, and the Belgian company IFG Cresco. The drive unit of the device is based on components from the Dutch company Ridder – a world leader in the production of gear motors.

Application: Modern solutions used by our company allow the installation of curtains at a height and shape in accordance with the user’s individual requirements. We offer several types of fabrics with different parameters for shading and thermal insulation for use with all crops.

Control: The unit is controlled automatically using a climate controller that receives signals from temperature, humidity, light, or programmable clock sensors. The curtain systems we propose create optimal climatic conditions for crops during the day and night, also enabling the reduction of production costs as much as possible.

| Length | 10m, 16m, 20m, 30m |

| Coverage | 10mm polykarbonat kanal, 16mm polykarbonat kanal, Plastfolie 180μm |

| Curtains | With, Without |

Commercial Greenhouses

Norhage Industri

Our experts are ready to assist you with selecting the best match for your growing operations.

Call us today and we’ll jumpstart your project!