Destackers

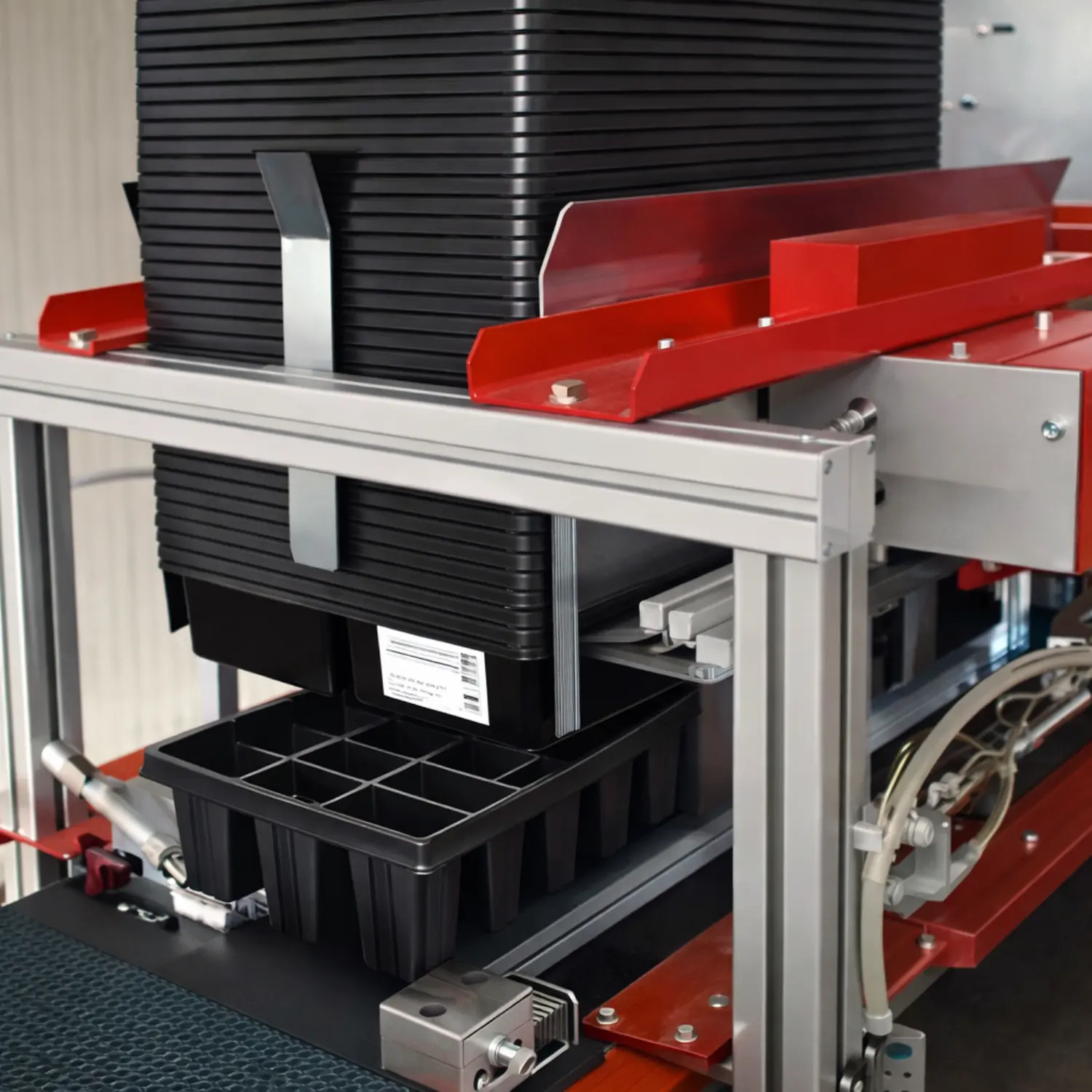

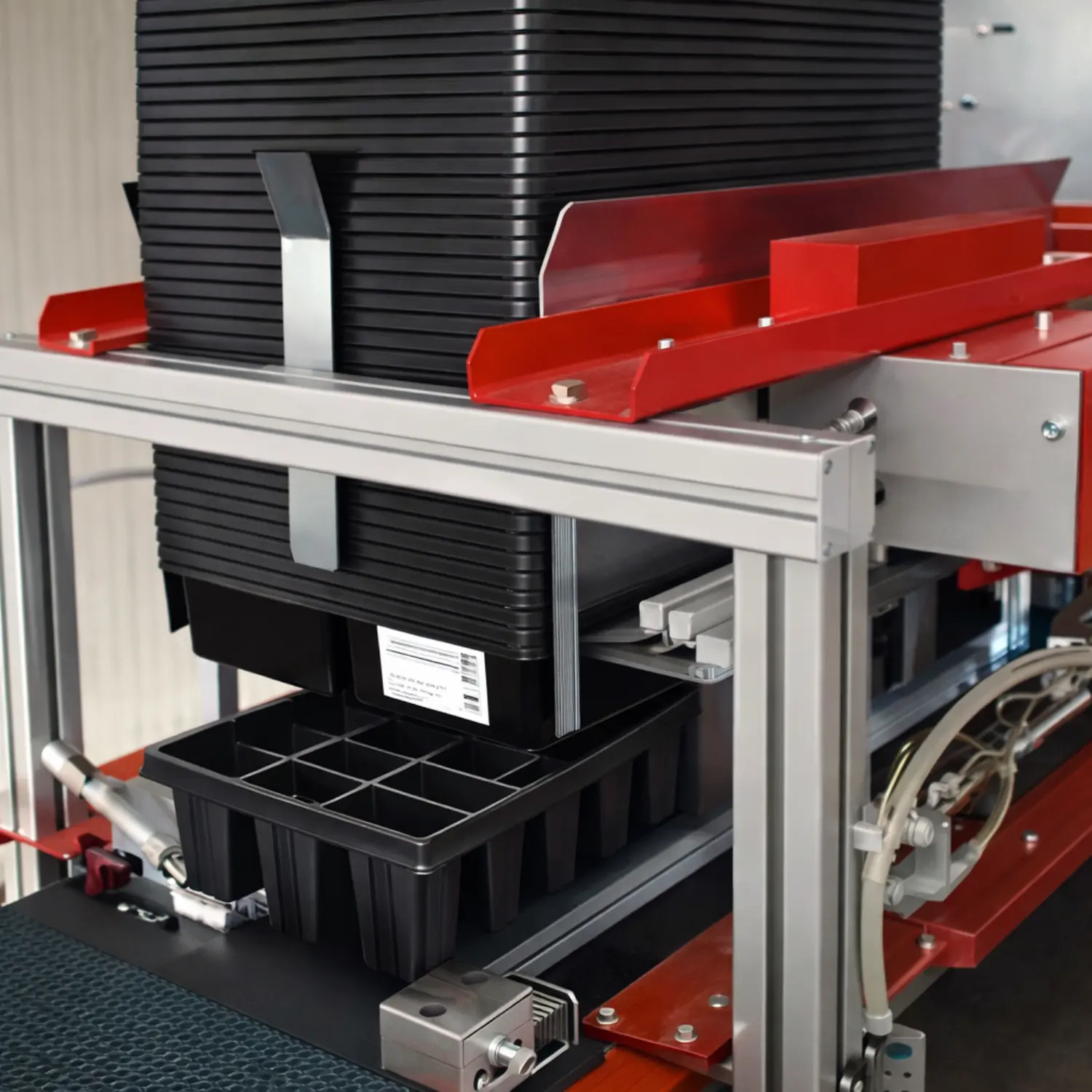

Industrial destackers are specialized automation components designed to precisely separate and individualize stacked trays, pots, and containers within a production line. These systems serve as the critical entry point for automated nursery and greenhouse workflows, ensuring a consistent supply of containers to downstream equipment.

System Overview

This category encompasses a range of technologies, from pneumatic units for standard polystyrene trays to high-performance electronic systems governed by Programmable Logic Controllers (PLC). These machines are engineered to handle various material types, including rigid plastic, polystyrene, and thermoformed containers, with adjustable settings to accommodate diverse dimensions and formats.

Positioned upstream of fillers, seeders, and transplanting lines, these systems eliminate the bottlenecks associated with manual container handling. By maintaining a synchronized flow of materials, they support the high-speed requirements of modern controlled-environment agriculture (CEA) and large-scale nursery operations.

Key Benefits for Professional Use

Process Repeatability: High-precision electronic and pneumatic controls ensure reliable separation, minimizing machine downtime caused by container jams or double-feeds.

Operational Scalability: Systems offer variable production capacities, with high-performance electronic destackers capable of processing up to 1,200 units per hour.

Seamless System Integration: Designed for modularity, these units easily interface with loading belts and subsequent seeding or transplanting stations.

Labor Efficiency: Automating the repetitive task of container separation allows technical staff to be redeployed to high-value production monitoring roles.

Versatile Format Handling: Adjustable mechanisms allow for rapid changeovers between different tray densities and pot sizes, supporting diverse crop cycles.

Typical Applications

Commercial Greenhouse Propagation: Automated tray preparation for high-volume vegetable and ornamental seedling production.

Nursery Transplanting Lines: Integration with specialized mechanisms for inserting thermoformed pots into carrier trays prior to soil filling.

Industrial Seeding Operations: Providing a continuous feed of polystyrene or rigid plastic trays to high-speed vacuum or drum seeders.

Forestry and Specialty Crop Production: Handling deep-cell containers and specialized tray formats used in silviculture and nursery reforestation projects.

Technical Consultation and Project Support

Successful automation requires precise alignment between container specifications and equipment mechanics. Our technical team is available to discuss specific project requirements, including system layout, throughput optimization, and the integration of destackers into existing production architectures.

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.