PVDF Polyvinylidene Fluoride

PVDF (Polyvinylidene Fluoride) is a high-performance thermoplastic known for its exceptional mechanical strength, thermal stability, chemical resistance, and hygienic properties. Ideal for industries requiring durability and high-temperature performance.

What is PVDF (Polyvinylidene Fluoride)?

PVDF is a premium, high-temperature engineering plastic offering an unmatched combination of mechanical, thermal, and electrical insulation properties. Manufactured without plasticizers or flame-retardant additives, PVDF is highly pure and safe for contact with food products. Its versatility allows it to be customized with additives or adhesive surface coatings to enhance its applications.

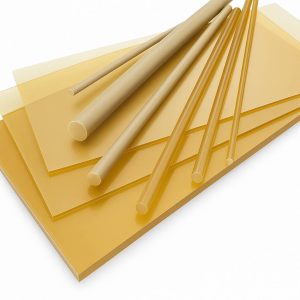

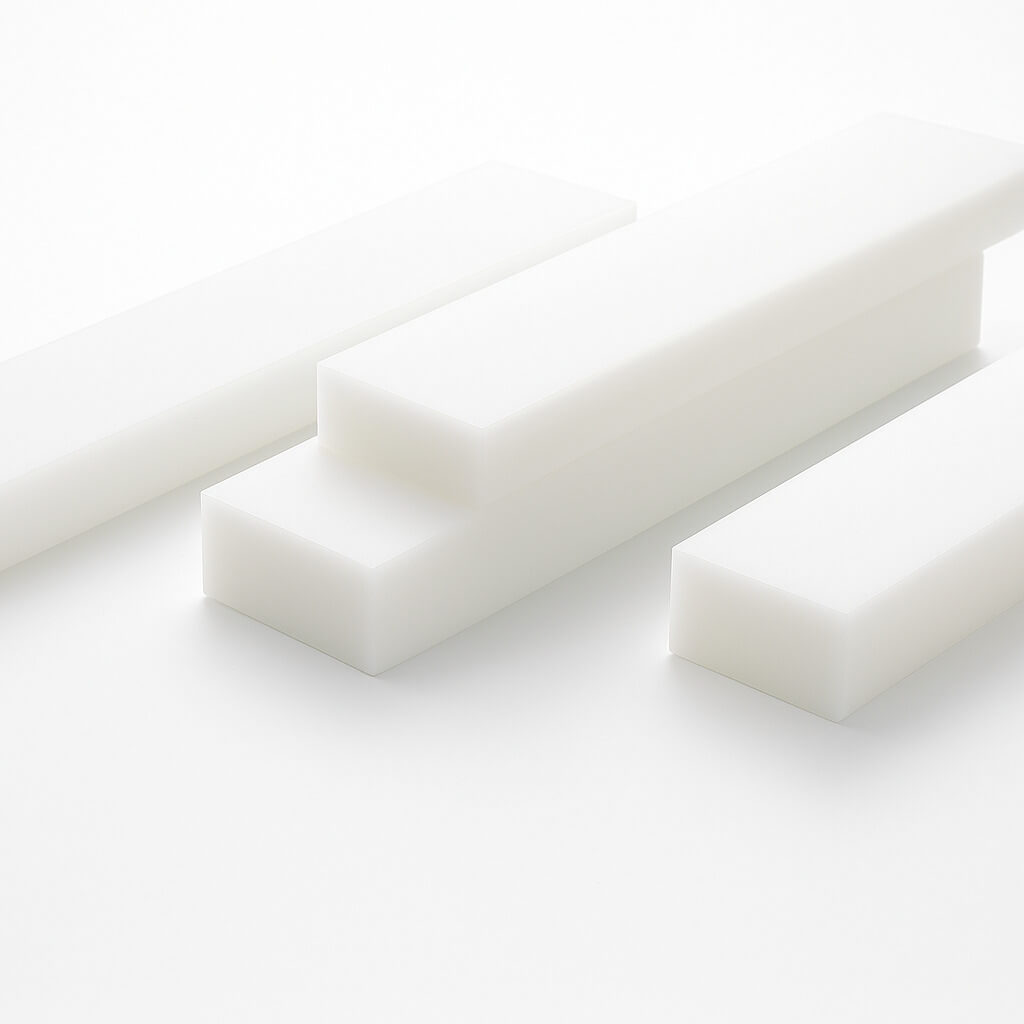

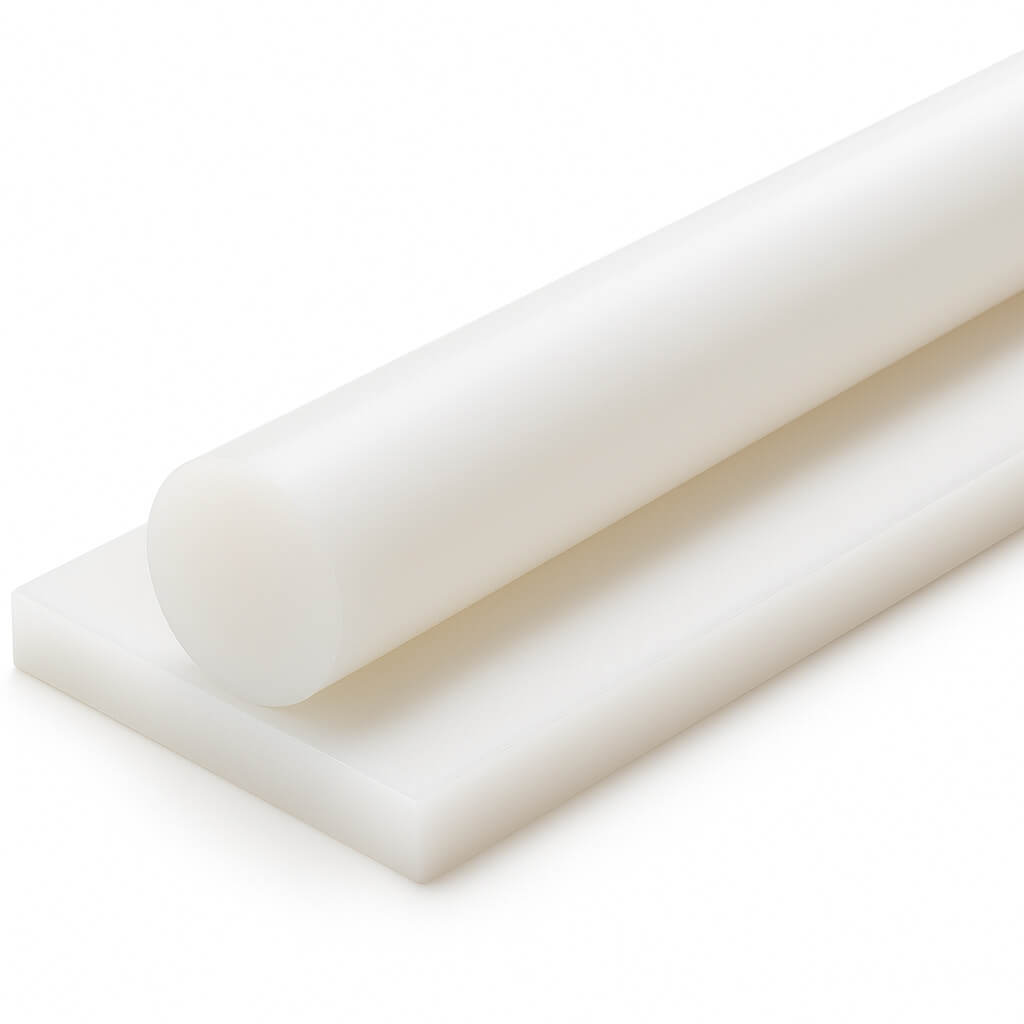

Available in various forms, including sheets, rods, square tubes, U-profiles, welding rods, and coils, PVDF is widely used across diverse industries due to its durability and adaptability.

Applications of PVDF (Polyvinylidene Fluoride)

Chemical Industry

PVDF excels in the chemical industry for manufacturing components like pump casings, impellers, storage tanks, and liners for aggressive chemical containers. Its outstanding resistance to harsh chemicals makes it a go-to material for galvanic systems and cleanroom technologies.

Oil and Gas Industry

The material’s high mechanical strength and low friction coefficient make PVDF suitable for piping systems, seals, and gaskets in environments requiring exposure to extreme temperatures and pressures.

Medical and Food Industries

PVDF’s hygienic properties and compatibility with food-grade standards make it ideal for medical equipment, food processing components, and pharmaceutical packaging.

Semiconductor and Electronics

Used in semiconductor technologies, PVDF provides clean, durable solutions for precision applications, including protective linings and components for high-purity environments.

Key Features of PVDF (Polyvinylidene Fluoride)

Characteristics and Benefits

- Excellent weldability: Ensures strong, seamless connections for industrial components.

- High-temperature resistance: Operates effectively from -20°C to +140°C, with customization for extreme conditions.

- Chemical resistance: Withstands exposure to aggressive substances, making it ideal for harsh environments.

- Low moisture absorption: Ensures stability and durability, even in humid conditions.

- Superior electrical insulation: Protects against electrical hazards in sensitive applications.

Why Choose PVDF for Your Industry?

PVDF stands out as a versatile and long-lasting material for industries requiring a balance of strength, hygiene, and resistance to challenging environments. Whether in chemical processing, medical technology, or high-purity manufacturing, PVDF delivers unmatched reliability and performance.

You may also be interested

Need help? Contact us

For personalized assistance or inquiries, our dedicated team is here to help. We’re committed to providing you with exceptional support and guidance, ensuring that all your needs are met efficiently and professionally.